BAC boss: Supply chain shortcomings slowing EV development

Battery-electric powertrains are currently too heavy to work in the BAC Mono platform, said Neill Briggs

Liverpool-based supercar maker says ‘we’re in’ once electric motors become widely available

Major manufacturers need to strengthen their supply chains before niche makers can develop electric sports cars, BAC co-founder Neill Briggs has told Autocar.

Liverpool-based BAC has been a key proponent of zero-emission powertrains in the low-volume sports car sector, with notable projects including the 2021 hydrogen-fuel-cell E-Mono.

According to BAC, this car would be more than 2.0sec faster than the track-focused Mono R around the Silverstone circuit, despite being 149kg heavier.

Briggs has now told Autocar that he is “convinced” that electric motors are “the [optimal] propulsion method”, but “where you get the power from is a highly complex question” – with hurdles including the supply of powertrains from major manufacturers as well as infrastructure uncertainties.

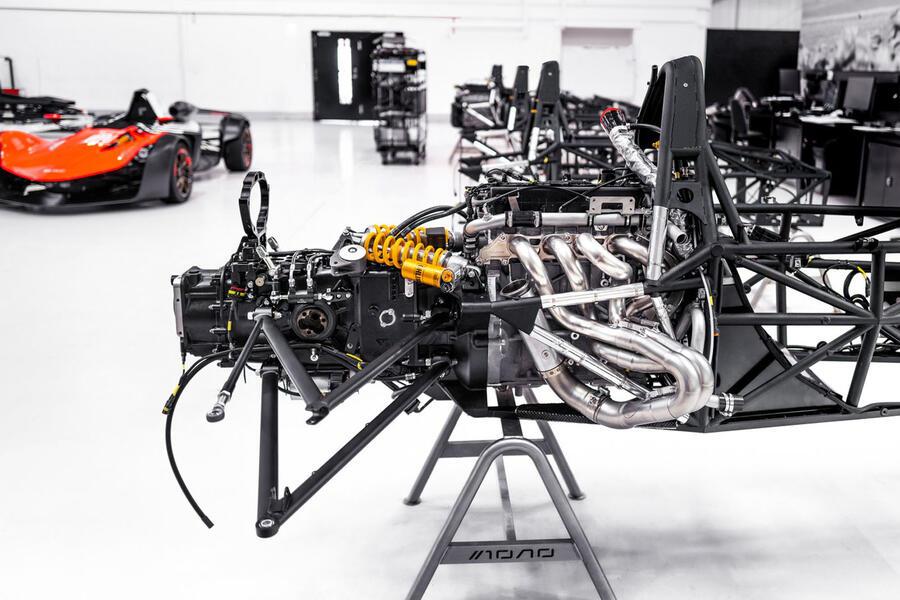

He said: “The biggest challenge for us is that with all the vehicles we’ve made to date, we relied on [major manufacturers] to develop a power unit. We take that power unit, we modify it, we bespoke it, we do all the things that we do to it – and that’s what’s in the car.

“In the EV space, we’re exactly as reliant and at the moment – I think it’s well documented – there are challenges in the supply chain for all the major brands and the [volume] ramp-ups that they need.”

He added: “The last thing that they want are the niche manufacturers knocking on their door, asking them to be able to secure those parts. Then we need to take those parts; we need to redesign the car, we need to re-test it, redevelop it, and so on and so forth. And that’s why the lead time for [electrification] is so long.

“When that’s available, we’re in. As we showed with our E-Mono fuel-cell electric vehicle concept, we can react pretty quickly.”

Briggs said he does not think the technology itself needs further development, but “the availability of the hardware needs to change”. He added: “Once that’s there, and it’s readily available, then of course we’ll be able to react and move forward.”

The weight of current battery-electric powertrains means they are not yet a viable solution for BAC, he believes, because the company would have to develop an all-new platform capable of supporting the additional mass.

He said: “The issue with fuel cells – which we’re still very, very strongly in favour of – is that the net [weight increase] in terms of changing an internal combustion engine for fuel cells is about 100kg. If we do that for a [battery-electric car], it’s more like 300kg or 400kg.

![]()

“The current platform could handle the fuel cell without having to re-engineer all the suspension and the tyres and the brakes because of the increased weight. The minute you go to a 900kg battery-electric vehicle, it’s a completely new, start-again car.

“That’s not to say that [BEVs aren’t] a possible solution. It just means it’s a solution further down the road. If we see the need for it moving forward, we’ll be guided by legislation.

“It’s a little bit Betamax and VHS: at some point, someone’s going to say it’s VHS, and everyone’s going to go down that route.”

With the lack of hydrogen infrastructure and the limitation of the Mono platform concerning battery-electric powertrains, BAC’s focus “is shifting more towards synthetic fuels” in the near term.

Briggs noted that it would currently take much less time for the company to validate its existing combustion engines for running on carbon-neutral synthetic fuels as a means of decarbonising its line-up. He said: “We can take a current internal combustion engine. We can run it on a dyno. We can put it in the car outside and we can go and do 10,000 miles of durability testing, strip it, and we’ll know the results within three months.

“Of course, we would need to re-engineer the car a little bit, but not a great deal.”

However, much like hydrogen, carbon-neutral fuels such as e-fuels are not yet widely available across the UK. Briggs said: “If these fuels were readily available at racetracks, for example, that [would] also change people’s perception of them because they could drive the car to a track, fuel up there, use their car at the track, fuel up again and can get back home on it.”