Mercedes In-Drive considers moving brakes into an EV’s electric motor

- Mercedes In-Drive relocates the brakes to inside an EV’s motor housing

- In-Drive remains a friction-based brake system

- In-Drive is in active testing with no timeline for production announced

Future Mercedes-Benz EVs might not have brakes sitting behind their wheels.

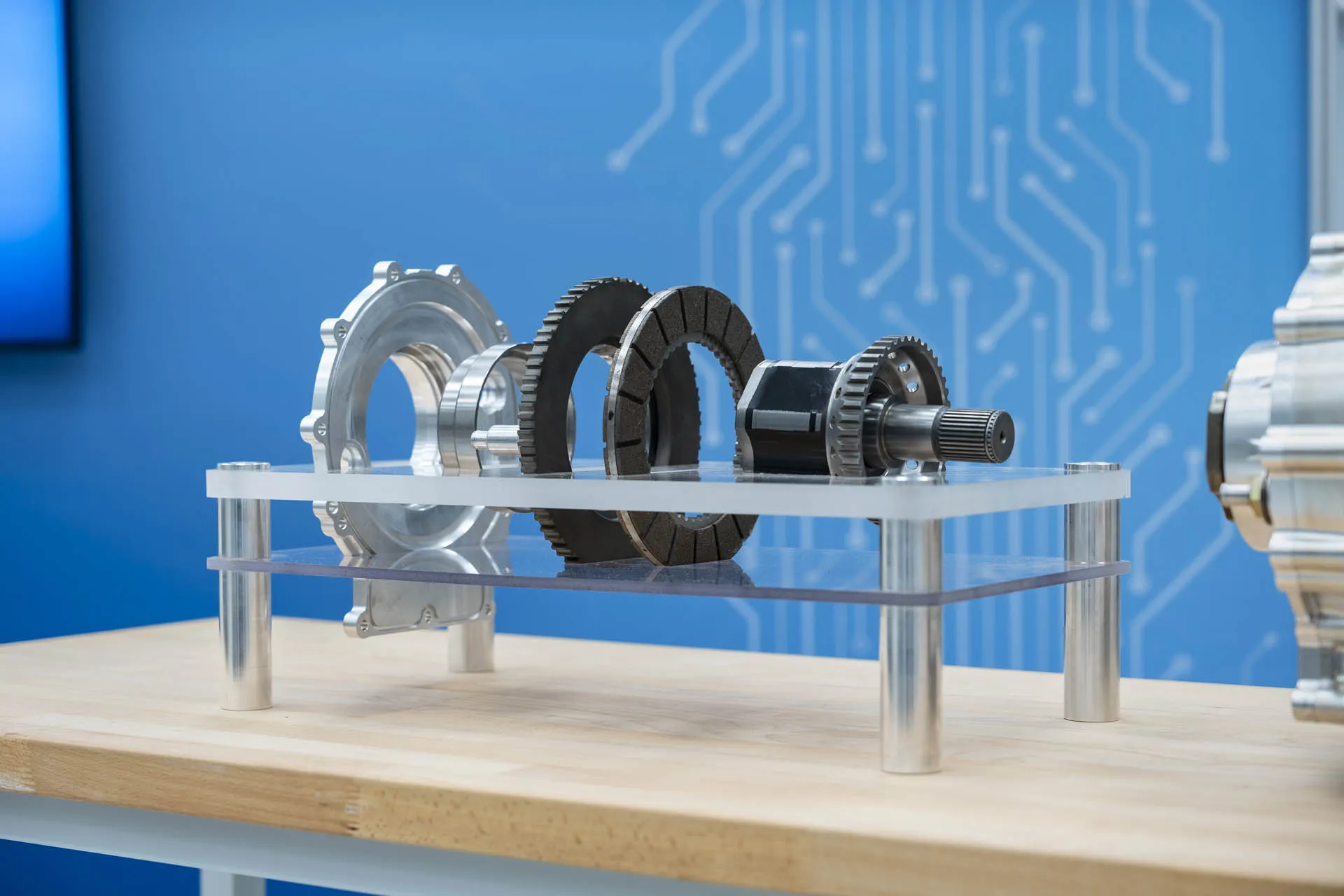

Mercedes-Benz engineers in Germany showed Motor Authority its latest EV drivetrain innovation called In-Drive. It’s a newly developed system that moves the brakes from behind the wheels to inside an EV’s motor casing. Mercedes is internally calling the system “the brake of the future.”

Engineers told MA the In-Drive system is already in active testing, but stopped short of confirming production or a timeline for production.

In-Drive is still a friction-based brake system with pads and metal rotors that slow the vehicle using pressure. But the entire system is sealed, enclosed within the EV drive unit’s housing. A rotor and pad bookend the electric motor within the metal housing. To keep things cool since there’s no airflow, the system is water cooled, though engineers are still playing with different fluids and viscosities as the unit needs to discharge a lot of heat without a radiator.

Only about 2% of braking is mechanical for an EV, while 98% can be handled by regenerative braking, according to Mercedes’ engineering team.

Today’s EQS is capable of up to 290 kw of recuperation through the regenerative braking system, while tomorrow’s 2026 CLA-Class EV will be capable of 200 kw of recuperation.

Said to be designed for the lifetime of the vehicle, which Mercedes defines as 15 years or 186,400 miles, this type of system could lower operating costs. The system’s pads last longer than today’s brake pads as they encompass the entire disc and thus have more surface area.

Mercedes designed the system be able to mount to the center of a front axle sans electric motor for single-motor rear-wheel-drive applications. Moving the braking system to the center of the vehicle will displace and remove unsprung mass, which in turn will improve handling.

Mercedes said today the system is more expensive than traditional brakes, but the goal is to bring the cost down to be equal to traditional brakes.

Mercedes-Benz paid for travel and lodging for Motor Authority to bring you this report